Foam

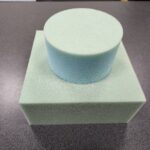

EVA (Ethylene Vinyl Acetate) and PE (Polyethylene) foams are versatile, lightweight materials ideal for CNC cutting. EVA foam is soft, flexible, and impact-resistant, making it perfect for applications like custom packaging, cosplay armor, gaskets, and padding. PE foam, on the other hand, is firmer than EVA with excellent durability, water resistance, and shock absorption, making it a top choice for protective cases, industrial inserts, and flotation devices. Both foams machine cleanly with CNC routers and knives, allowing for precise cuts and custom designs. Whether for industrial, commercial, or creative use, EVA and PE foams offer reliable performance in a variety of applications.

We don’t list these foams in our online store, but send us your files and we can email you back a quote.

Foam Grades

Foams come in different grades measured by their density. The higher the density, the harder the foam is. They are available in thicknesses of 3mm – 40mm

EVA Foams

- EVA30 – Very soft, like your skin when flexing your muscle

- EVA45

- EVA60

- EVA75

- EVA90

- EVA105

- EVA120

- EVA150

- EVA190

- EVA220

- EVA260

- EVA350

- EVA400 – Very hard, like a soft wood

PE Foams

- PE30 – Similar to EVA75 – EVA90

- PE45

- PE60

- PE75

- PE90

- PE120

- PE140

- PE180

- PE250 – Similar to EVA 400

Foam Colours

Foams are available in a range of colours with the most common being Greys and Blacks. It can also be purchased in dual-laminate which is 2 different coloured foams laminated together. We typically use 6mm Dual-lam (3mm top and 3mm bottom) which we can then machine through the top colour to reveal the bottom.

Processing

Foams can be processed on our laser cutters, our router cutters, or with our oscillating knives. All of which are computer controlled.

Laser cutting melts the edge so it is not our preferred cutting method. It is useful for etching a logo into the face of foams.

Router cutting gives us the ability to put detail into the face such as teak-lines, diamond patterns, and boat names into your boat matting. We can router through the first layer of a dual-laminate foam to show the second colour. This gives great effect with control of depth far superior to that of laser cutters.

Our oscillating knife gives the cleanest cut (routers pull at the foam, lasers melt it) but can’t do the etching or engraving of the other machines.

At Axis we are lucky enough to have all 3 of these technologies so we can get the best of all world when it comes to cutting these foams.

Uses

- Boat Matting

- Cockpit cushions

- Gaskets and Seals

- Fruit handling machinery parts

- Toolbox Inserts