About

Oscillating tangential knives are a computer-controlled cutting tool designed for intricate and accurate cutting of soft to semi-rigid materials. Unlike rotary tools, it uses a high-frequency, up-and-down oscillating blade (like a jigsaw) controlled by a tangential (direction-following) axis. This means the blade physically rotates to align with curves and angles in the design, allowing clean, crisp edges even on dense, thick, or fibrous materials. It’s especially valuable where drag knives struggle—like with foams, rubbers, textiles, leather, and corrugated cardboard.

The oscillating motion rapidly moves the blade up and down, slicing through material with less friction and tearing, while the tangential control ensures the knife angle matches the tool path. This combo makes an oscillating tangential knife perfect for detailed contours, sharp corners, and thick stacks. It handles variable materials and layered cuts without distortion, maintaining high precision over large areas.

How

Oscillating tangential knives are suited to vector cutting softer materials. Vector cutting follows paths defined in CAD files, ideal for parts, signage, and detailed shapes.

Our machines use stepper motors to move the cutting head along the X, Y, and Z axes, as well as turning the blade to the correct direction (the tangential part) using software that interprets files from vector design programs. Speed, and pulse frequency can be tuned to suit different materials and thicknesses, giving excellent control over the finish. Our machine can operate with or without the oscillating function.

Benefits

- Easily cuts soft materials without burning like a Laser

- Cuts cleanly through soft or dense materials with precision.

- Handles sharp corners and intricate shapes with ease.

- Can cut sharp internal corners unlike a CNC Router

- Low cutting pressure protects delicate or compressible materials.

- Efficiently cuts thick or stacked materials in one pass.

- Blade rotates tangentially for accurate, repeatable cuts.

- Works on rubber, foam, felt, leather, cardboard, more.

- Quiet, clean, and safe—no dust or chips.

- Great for prototypes, short runs, or custom jobs.

- The kerf width is 0

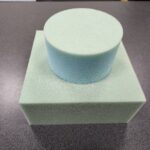

Items we use our our knife for include: Engine gaskets, EVA foam tool drawer inlays, Pelican case foam inserts, Acoustic felt wall tiles, Truck mud flaps, Rubber floor mats and Ute deck mats, Automotive boot liners, Anti-vibration pads, Textiles, Corrugated packaging inserts, and fruit handling machinery components.

With the precision of our Oscillating tangential knives, we can cut an extensive range of materials with ease and precision. Explore our Materials A–Z to see the full list of what we mainly work with. If it is not listed there, ask us here and we can advise or trial new materials for you.

Whatever you need cut, etched, engraved or fabricated, just send us your files — we’ll put the right machine to work, drawing on the full range of our capabilities to deliver precision and quality.

If the product is not suitable for our Oscillating tangential knives, we can probably process it with our Laser cutters or CNC Routers.