Introduction

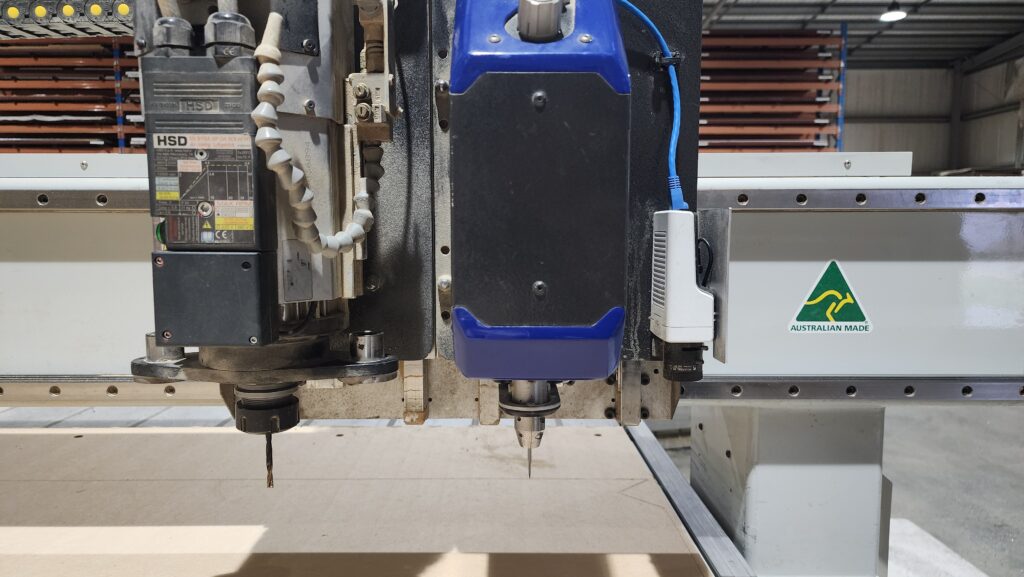

CNC routers are precision machines that use computer-controlled movements to cut, carve, and engrave materials such as wood, plastic, metal, and composites. Machinists program the path the router will follow using CAD (Computer-Aided Design) software, which translates designs into a set of instructions for the machine. These instructions control the router’s movements along the X, Y, and Z axes, allowing the machine to execute precise cuts with minimal human intervention.

CNC is an acronym for Computer Numerical Control.

Why A CNC Router Stands Out

One of the CNC router’s key strengths is its ability to perform pocketing. This involves removing material from a specific area to create a recess or cavity, which is especially useful in tasks such as making cavities for hardware or creating inlays. With a CNC Router, we can precisely control the depth of this pocket. CNC routers are also highly effective at cutting profiled edges—where the router bit follows a programmed contour to create consistent, smooth, and often decorative edges. This makes them ideal for applications like cabinet making, signage, and furniture production. For example, machinists can use specialized router bits to create intricate edge profiles on furniture pieces, producing both functional and decorative effects.

Additionally, CNC routers excel at detailed engraving and 3D carving, allowing for the creation of highly intricate designs in a wide range of materials. However, CNC routers do have certain limitations. Because they use round router bits, they typically leave a small radius at the internal corners of cuts, meaning they can’t achieve perfectly sharp, square corners. This can be a drawback in situations where precise, right-angle internal corners are required, such as in certain types of joinery or mechanical parts. Another limitation is that CNC routers may not be as effective for deep milling or drilling operations that require precise vertical control, such as drilling deep, fine holes or creating tight internal features with very tight tolerances.

Final Thoughts

Despite these limitations, CNC routers remain an indispensable tool in modern fabrication, offering efficiency, flexibility, and precision for a wide range of applications, from custom one-off designs to large-scale production runs. Their ability to handle diverse materials and perform a variety of cutting tasks with consistent accuracy makes them a core component in industries like cabinetry, signage, automotive, and aerospace.

Our Machines:

Here at Axis, we have 6 CNC routers:

C1

-

- 2.4m x 1.2m bed size (Processing size is slightly higher)

- Vacuum bed

- Automatic tool changer

- 2.5D (X, Y, Z movements but unable to tilt the cutting tool)

C2

-

- 3.05m x 2.03m bed size (Processing size is slightly higher)

- Vacuum bed (twin vacuum pumps)

- Quick tool changer

- 2.5D

C3

-

- 2.4m x 1.2m bed size (Processing size is slightly higher)

- Vacuum bed

- Manual tool changes only

- Floating Head.

- 2.5D

C4

-

- 6.1m x 1.83m bed size (Processing size is slightly higher)

- Vacuum bed (twin vacuum pumps)

- Quick tool changer

- 2.5D

C5

-

- 2.4m x 1.2m bed size (Processing size is slightly higher)

- Vacuum bed

- Only runs a tangential oscillating knife

- 2.5D

C6

-

- 6.33m x 2.55m bed size (Processing size is slightly higher)

- Vacuum bed (triple vacuum pumps)

- Automatic tool changer

- Tangential oscillating knife

- Camera alignment system

- Air assisted floating head

- 2.5D

With the precision and versatility of our CNC routers, we can cut an extensive range of materials with ease and precision. Explore our Materials A–Z to see the full list of products that we mainly work with. If it is not listed there, ask us here and we can advise or trial new materials for you.

Whatever you need cut, etched, engraved or fabricated, just send us your files — we’ll put the right machine to work, drawing on the full range of our capabilities to deliver precision and quality.

If the product is not suitable for our routers, we can probably process it with our Oscillating tangential knife or on our laser cutters.